This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Membrane Keypad Design Guide

The Diamond HMI Membrane Keypad Design guide provides engineers who have little or no experience of membrane keypad design, with an insight into the design parameters they need to consider.

Our Diamond HMI Membrane Keypad Design Guide covers areas such as the artwork design, key styles including embossing, force/travel considerations and other key elements that need to be included when preparing CAD drawings.

The Membrane Keypad Design Guide and additional raw material datasheets can be downloaded using the links opposite. This information will give designers an overview of all the elements that must be considered when specifying a membrane keyboard design.

Our own UK Membrane Keypad design team are available to support you at any point in the process from simple concept discussions to detailed considerations of membrane keypad design.

We also offer our Membrane Key Design Selection Tool which demonstrates the different styles of key embossing and methods of providing a key’s tactile response. The Selection Tool can be ordered by calling our Product Management team on 01477 505206 or use the enquiry form below.

See sample information from our Design Guide below.

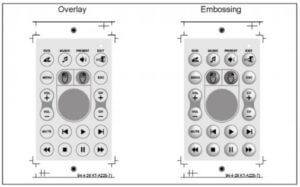

Embossing

In many applications it is desirable to emboss the keys of a switch. The phrase “Pillow Embossing” is used to describe keys that are raised and flat on the top. This is most commonly used with metal domes. “Rim Embossing” is used to describe only the border of a key being raised and is frequently used in non-tactile applications but not limited to . “Dome Embossing” is when the button is formed into a raised circular dome shape.

Mechanical Tolerances

Steel rule dies are normally used to fabricate the various layers of a membrane switch. Standard tolerances should be +/- 0.38

1 mm (.015”). Tolerances of +/- .254 mm (.010”) can be held on critical dimensions such as the perimeter or cut-outs.

Hole centre to hole centre tolerances of +/- .127 mm (.005”) can be held. Tolerances on very large parts will be greater.

The switch layers under the overlay will typically be fabricated smaller than the overlay. This allows for die cutting and assembly tolerances. All layers will typically be inset from the overlay at all edges and cut-outs by .015 inch

If you require more information on membrane keypads and design features that can be incorporated click the box below. Diamond HMI has a combination of over 50 years experience within the membrane keypad market. Our engineers can support you throughout the whole design process, to ensure your design meets all requirements for full operation in intended environment.

Download our Design Guide

Click the button and fill in your details to download our design guide