This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Membrane Keypad Design and Construction

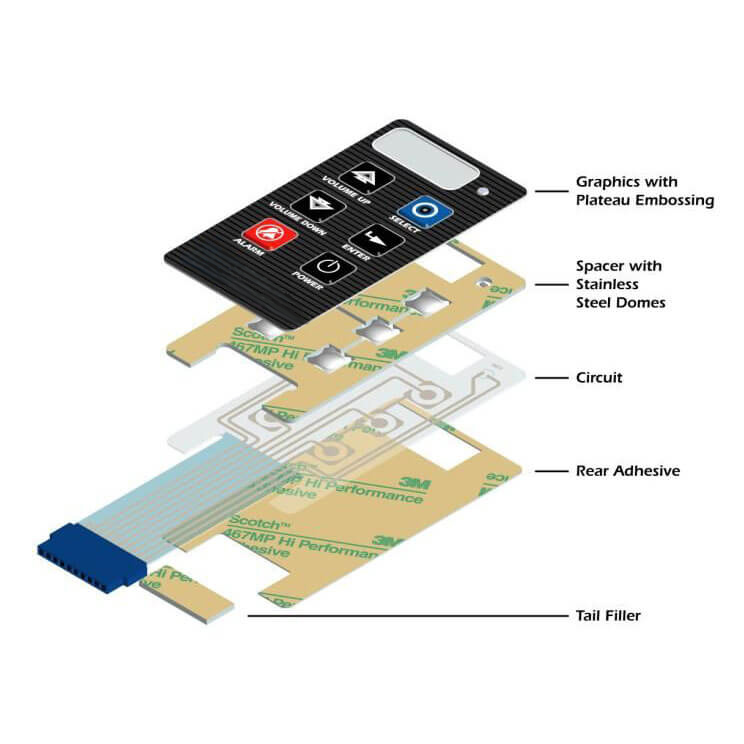

Membrane keypads, which are also referred to as membrane switches or membrane keyboards, are made by printing coloured and conductive inks onto Polyester or Polycarbonate films. The top layer creates the graphical design whilst the lower layers contain the printed circuitry layers.

A membrane switch operates when electrical contact is made by pressing the finger onto the switch contact area and broken when the finger is released. With the addition of metal domes within the structure, it is possible to add a specific tactile response for each key.

Membrane Keypad Construction

The graphic layer (typically 0.125mm – 0.180mm thick) has printing inks on the reverse to prevent keypad wear.

There are options of fine and coarse surface texture with clear (unstructured finish) in particular areas to either enhance the look or provide a window through the material for Displays or changeable insert legends.

Specific areas on the graphic layer can also be embossed to help the user to locate the switch quickly. The embossing styles can be rim, pillow, or dome with braille if required.

The upper circuit is typically 0.050mm – 0.130mm thick material and acts as a seal for the circuit and can also have a shield printed on the top surface in conductive inks to act as an RFI shield. This can be connected to the tail, or have tabs to enable a conductive connection to the customer’s assembly.

An adhesive spacer is used to separate the upper and lower circuit or as a means of restraining the metal domes in place.

The lower circuit is made from either Polyester which is surface printed with conductive ink, a flexible Polyamide FPC plated and chemically etched double-layer circuit with gold plated connections or a multi-layer PCB. All types of the lower circuit can have LEDs strategically placed to provide a lighting effect. FPC / PCB circuits have the added advantage of being able to have components soldered to either side such as ribbon cable connectors etc.

Finally, the assembly then has a 3M adhesive specifically chosen to suit the customers housing material.

Developments such as the introduction of UV resilient and anti-microbial coated graphic layers and also thin-film light conductors known as “LGF” (Light Guide Film) can be integrated within the circuit. Rather than simple spot illumination, it is now possible to light whole areas of the overlay such as the switch area or even customers logo, to enhance the look of the device whilst still providing a thin membrane assembly.

Learn more about membrane keypads here.

Features which may be added to a Membrane Keypad design:

Membrane Keypads from Diamond HMI can include a range of additional design features.

Chemical & UV resistant materials – For Membrane Keypads used in harsh conditions.

Anti-microbial coatings – For Medical Applications.

IP rating up to IP67 – To prevent water ingress.

Tactile keys with Metal domes or Poly domes – To give user feedback of key presses.

Rim, Pillow, Braille or Dome key embossing – To improve a keypad’s aesthetics and to help users locate keys.

Integrated SMT LEDs. – To add user feedback.

RFI/ESD/EMC shielding layers – To add resistance to RFI and ESD.

NEW – Light Guide Film (LGF) backlighting – Illuminate whole key areas or logos.

Interchangeable legends and inserts – To allow the keypad to be used in multiple applications.

Integrated Flexible Printed Circuits (FPC’s) or PCB back panels – For easy mounting and easy integration.

Steel/Aluminium back panels with mountings – To easy mounting into electronic equipment.

If you would like to see samples of our keypads which utilise any of the above features please contact our Product Management team on 01477 505206 or use the enquiry form below.

Further help on designing membrane keypad download our Membrane Keypad Design Guide.